Perfect Fitting Scroll Saw Pieces

How do you get scroll saw pieces to fit together perfectly? There are some seasoned woodworkers out there who are saying “you stack cut them!” They are absolutely correct…except for one aspect in which they’re wrong. Let’s demystify the process (and talk about other useful tips) so you get better fitting pieces.

I may receive compensation for affiliate links.

Stack Cutting

First thing – What is stack cutting? It’s when you cut multiple boards at the same time. Since you cut them together, they should theoretically fit together. Here’s how to do it:

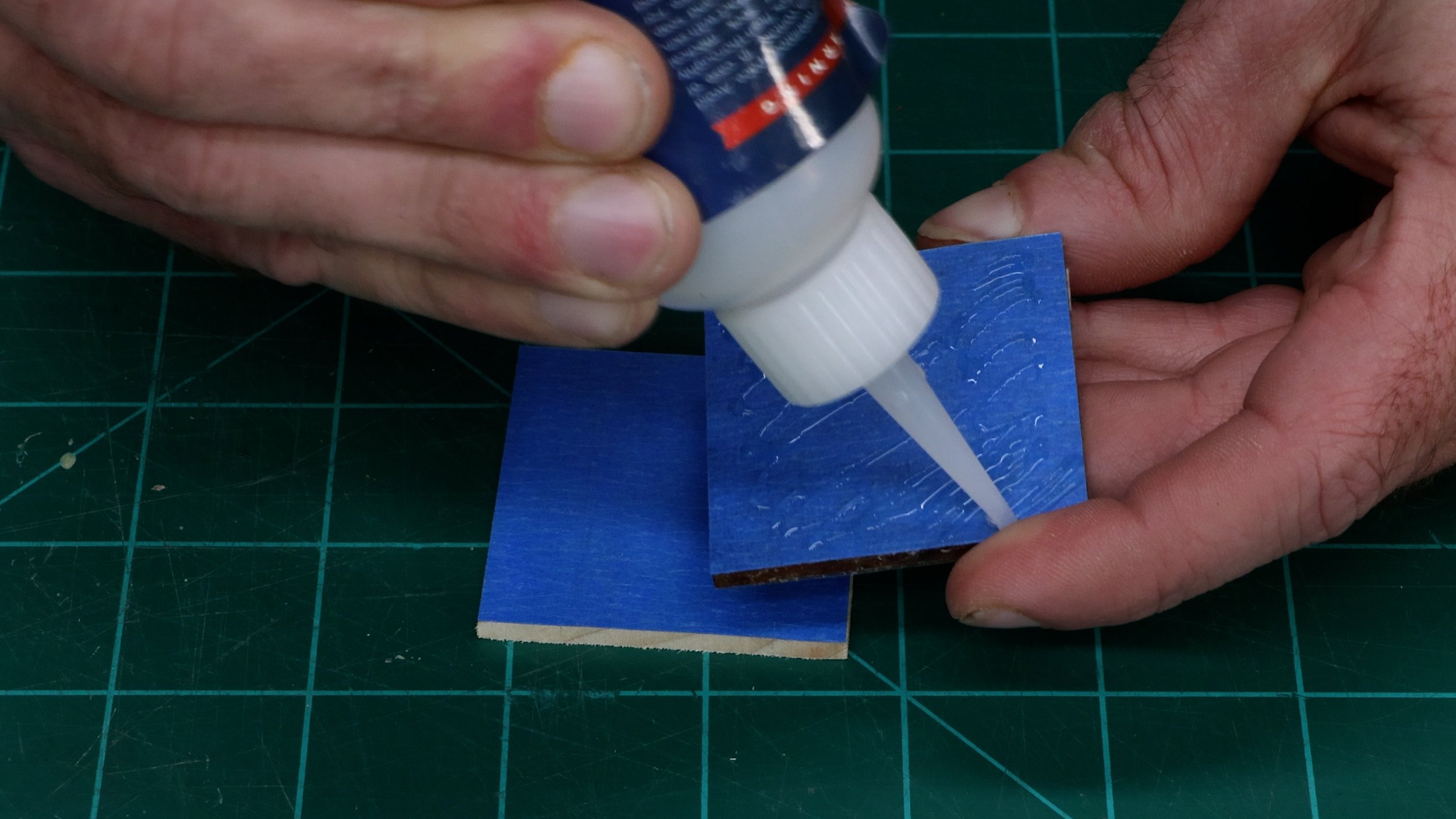

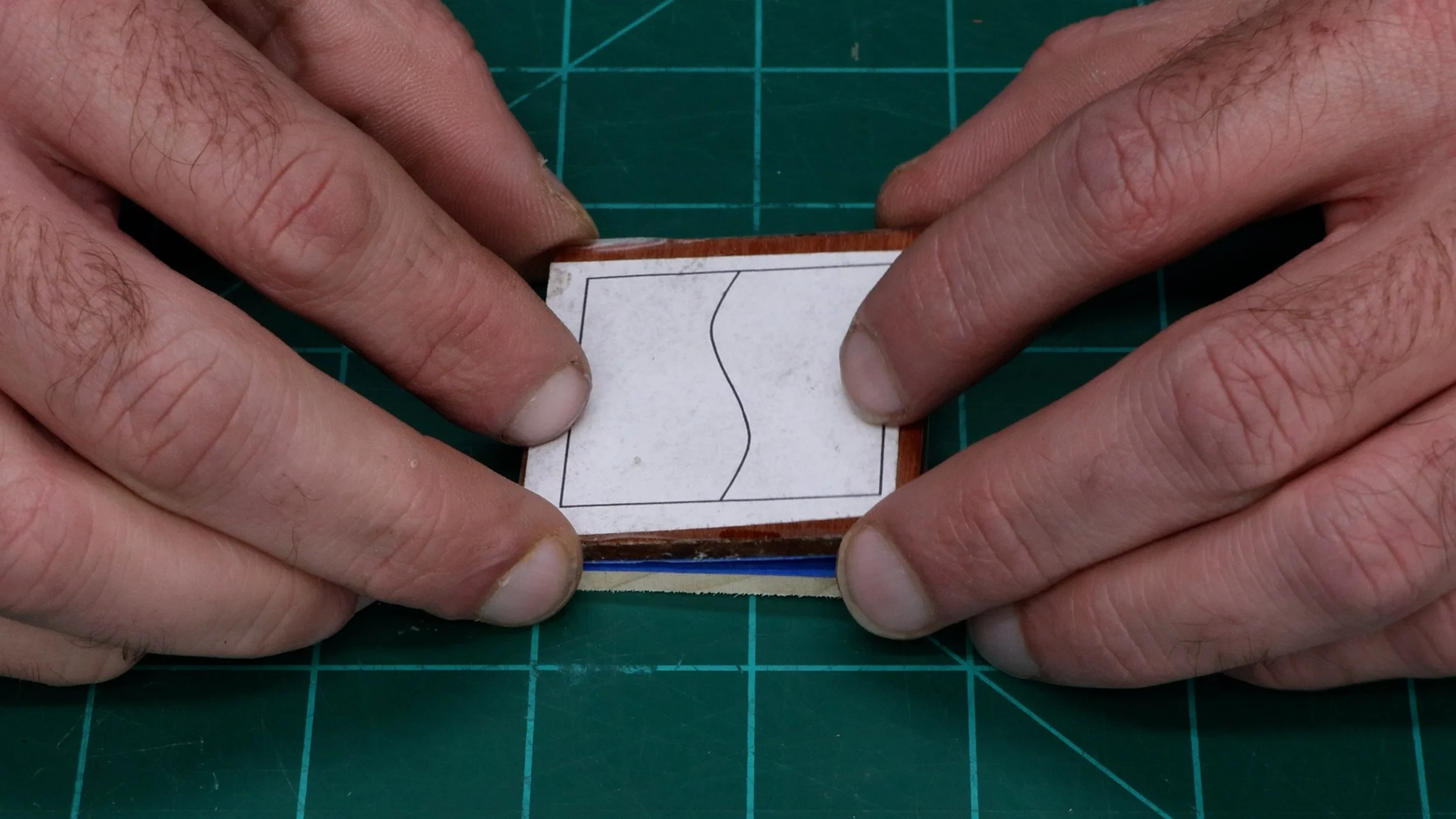

Put painter’s tape on both workpieces. Stick the two pieces together. Some people just tape them. I don’t like that method because they can slide around once you cut the tape. I put CA glue on the painter’s tape on one piece. It’s important to spread the glue around. A few drops of glue will hold the pieces just fine, but that’s not the reason for this. If we cut away the area that had the glue, the rest of our boards will separate. Put glue everywhere so it’s not a risk. I spray the other piece with accelerator. When the pieces are combined, the glue will instantly dry. Now, we’re ready to cut.

Cut the pieces and remove the tape. They should fit together cleanly, hopefully with no gaps! But there are some other tips to utilize and issues to overcome.

Blade Size

When stack cutting, I recommend using the smallest blade possible. How small will depend on the thickness of your pieces and the wood species. As the blade cuts, it isn’t just turning one board into two boards. It’s turning one board into two boards plus saw dust. The width of the blade is chewing away material. The more it chews, the higher the likelihood you’ll have gaps between the pieces.

Keep Moving

Make your cut in a quick, fluid motion. Don’t stop cutting partway through. Don’t hold the boards still while the blade is running either. It may seem like you’re not removing material, but you actually are just from the side of the teeth rubbing against the boards.

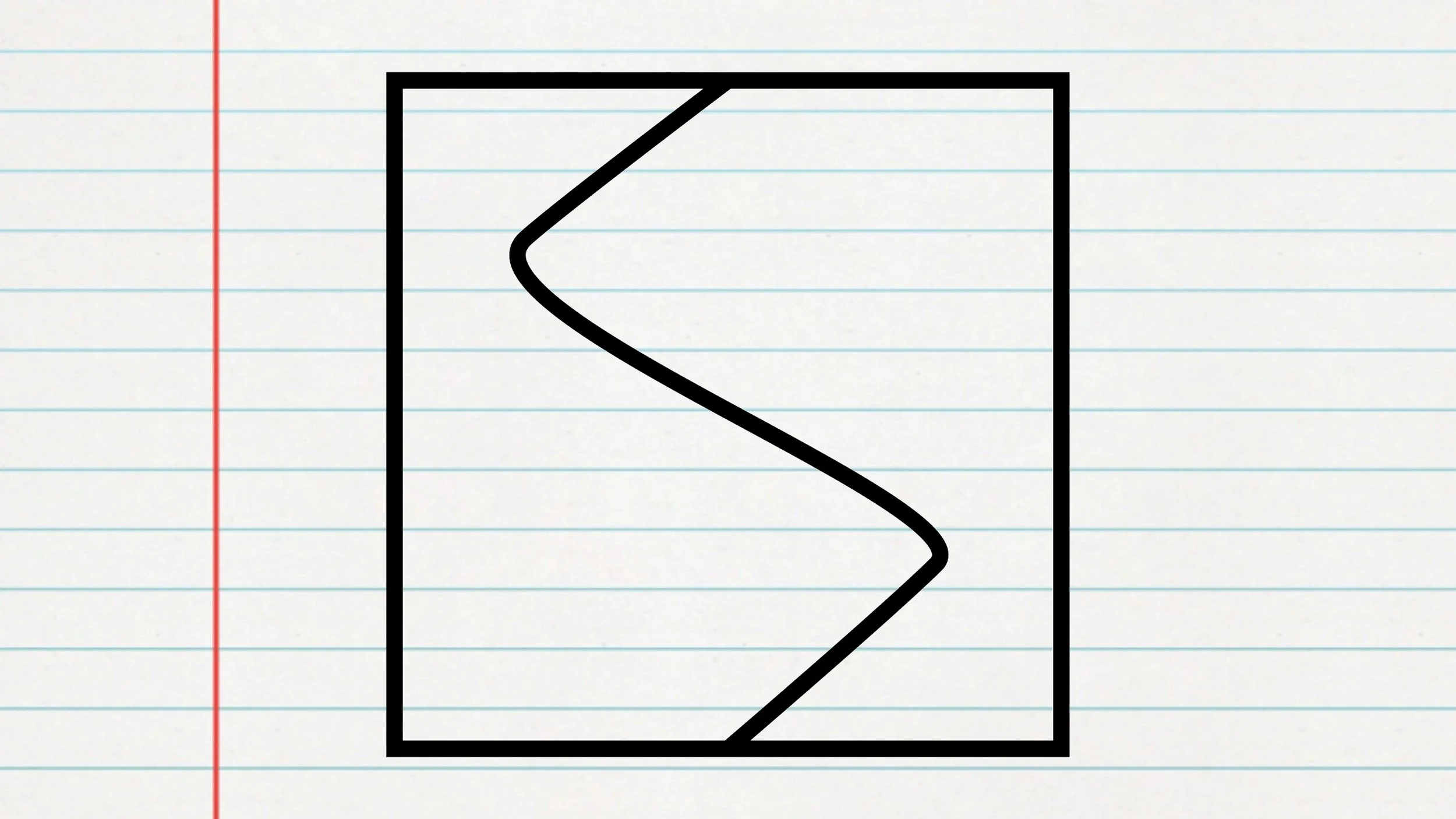

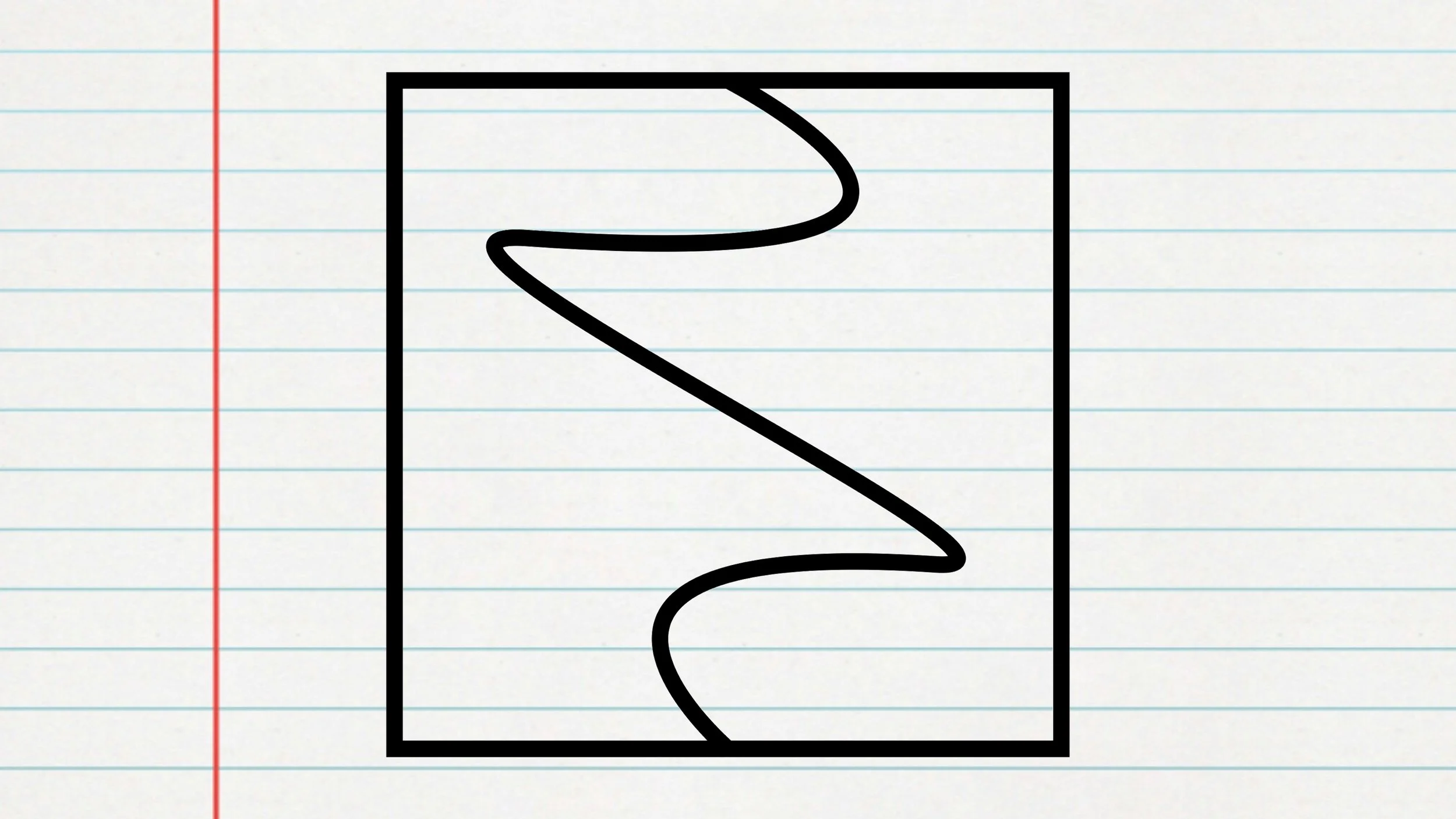

Avoid Sharp Turns

When stack cutting, the more curves you are cutting, the more likely you are to get gaps. The blade will eat away material as it turns. You can reduce the chances of gaps by turning the pieces quickly around curves. But if the curve is extreme enough, it doesn’t matter how fast you move, you’ll end up removing too much material. If you have sharp or tight areas that have to fit together, stack cutting may not be the answer.

Wrong Size Pieces?!

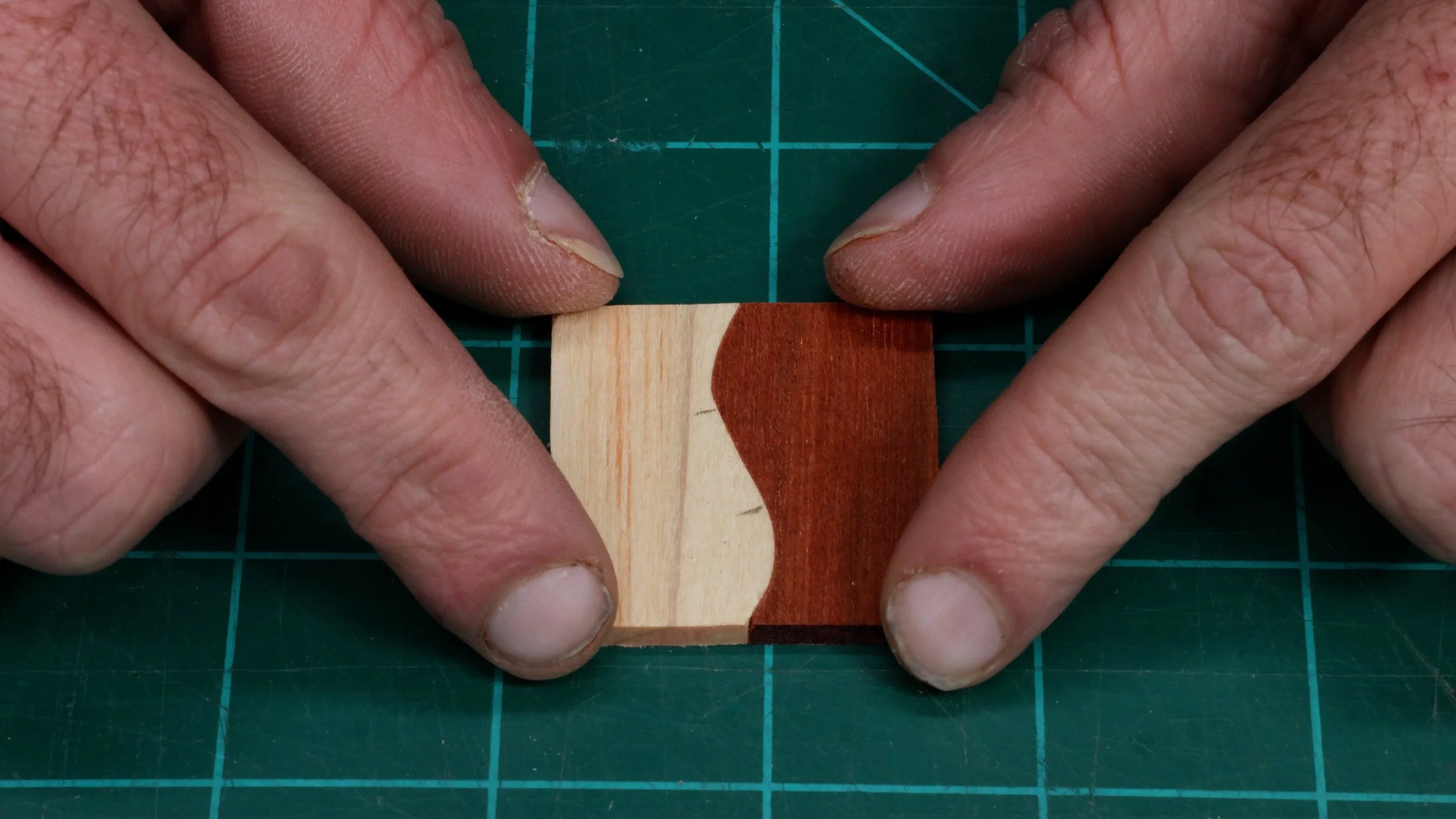

You stacked cut your pieces and followed the tips above. That’s it, right? Now you live happily ever after? Well, there’s an added complication. The saw blade turned some of the material into saw dust. Our pieces are going to be undersized.

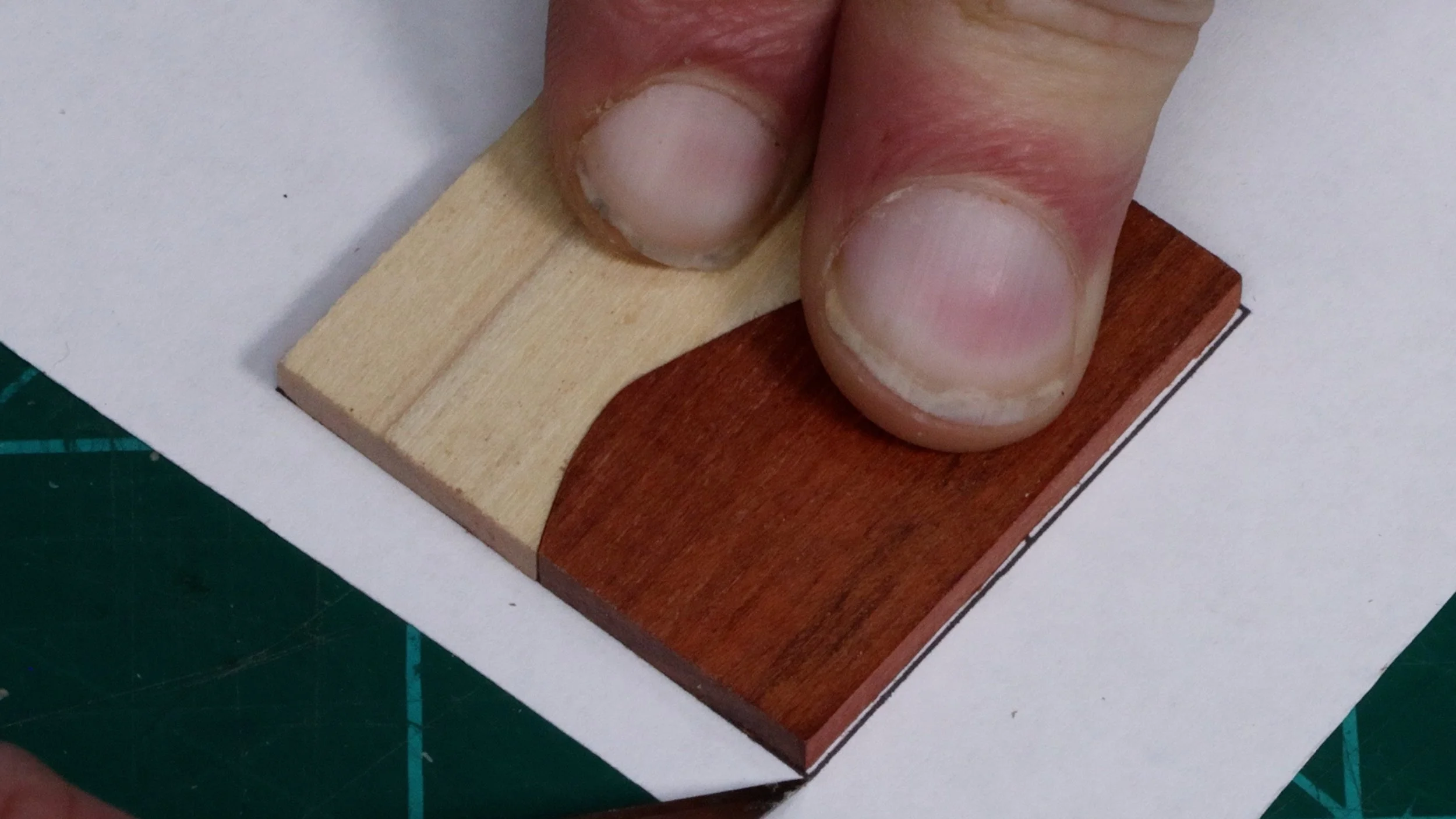

You can see it with this example. I put the pieces on top of my template. Everything is aligned perfectly on three sides, but you can see the fourth side has a small gap, about the same thickness as my saw blade. This may seem unimportant. In vacuum, maybe it is. But what if you have more than two pieces? Maybe you have another piece on the other side. And another one next to that one. This slight gap doubles, triples, quadruples…next thing you know the whole artwork is undersized.

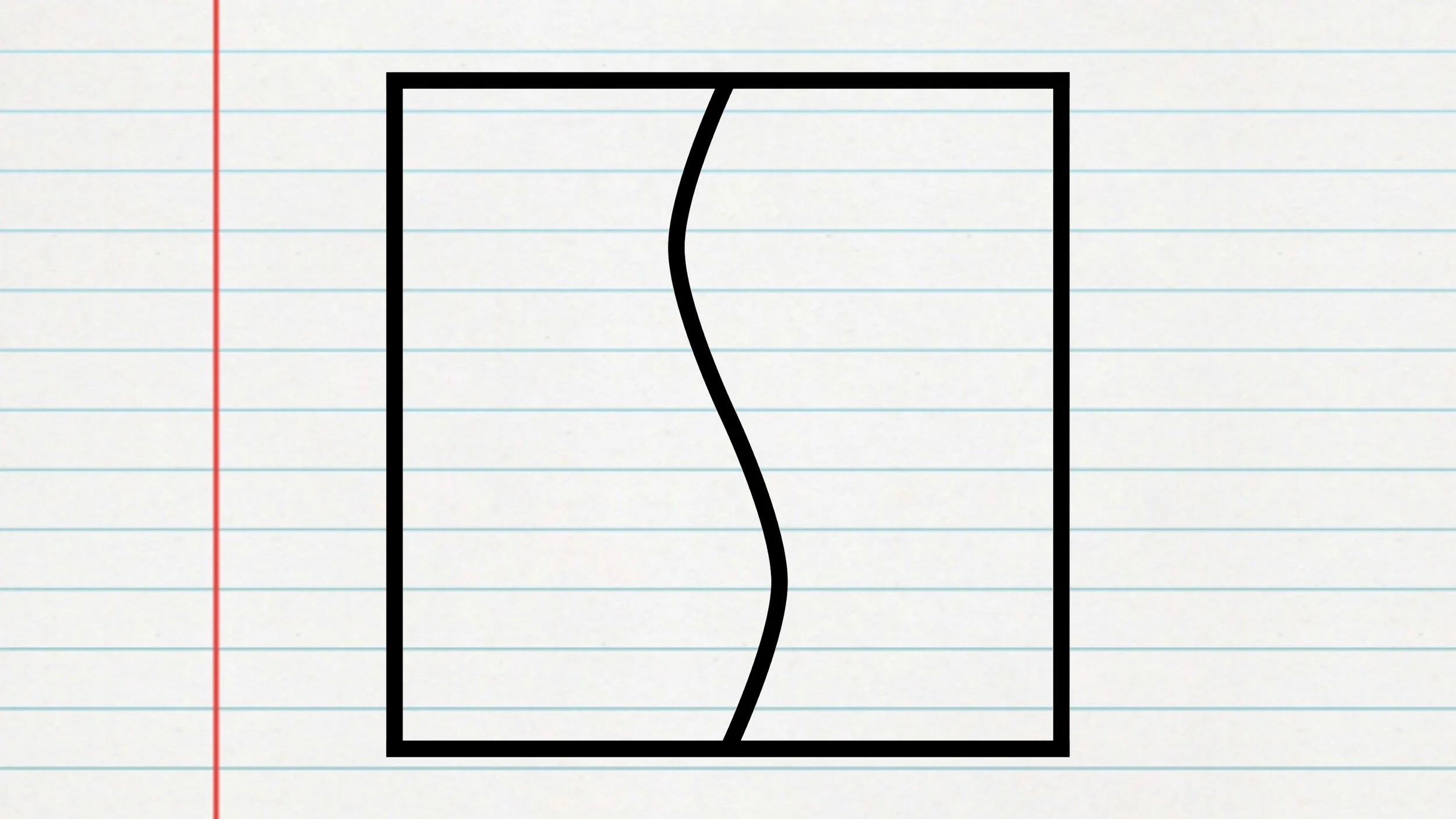

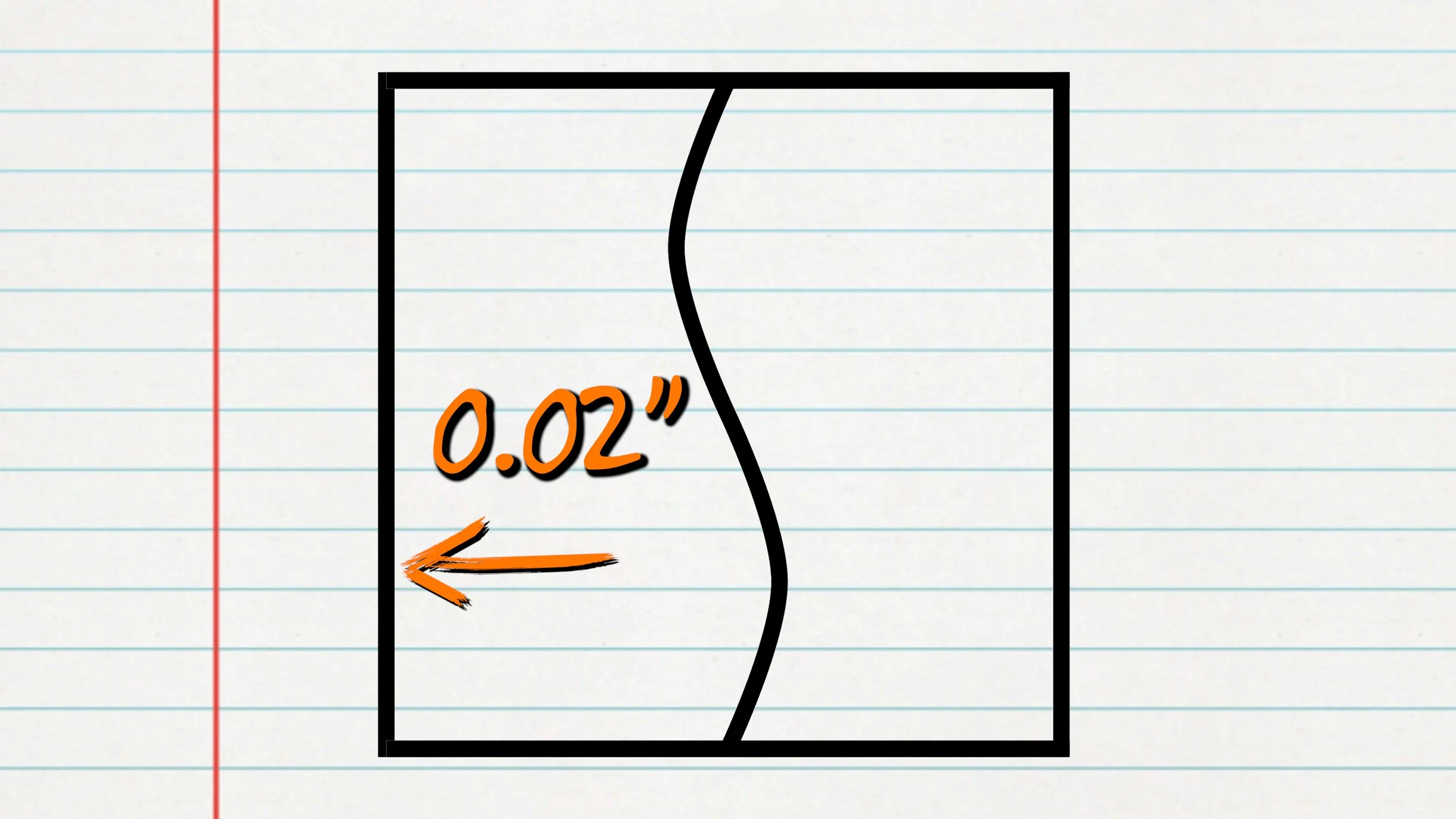

Scaling Our Scroll Saw Pieces

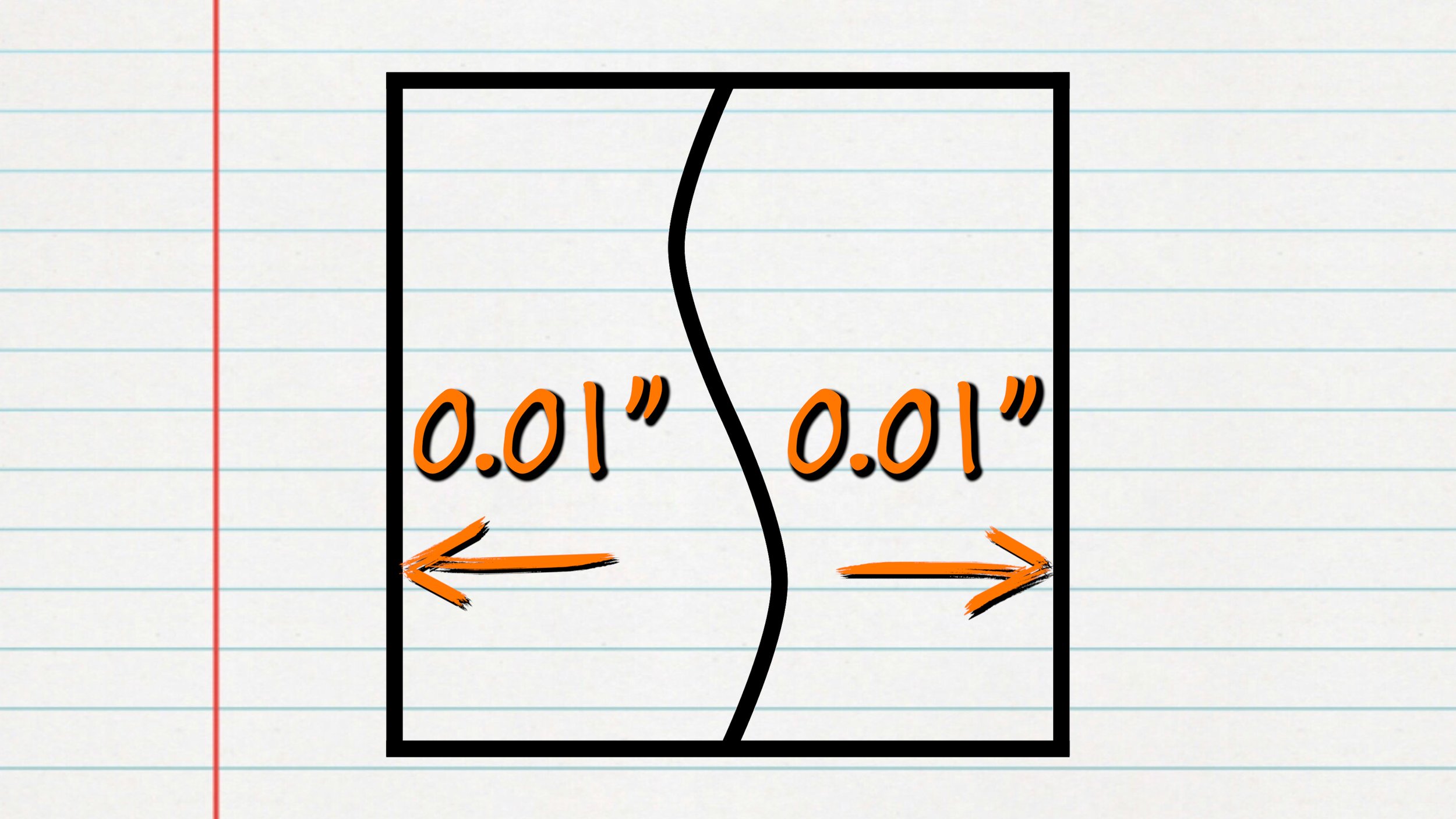

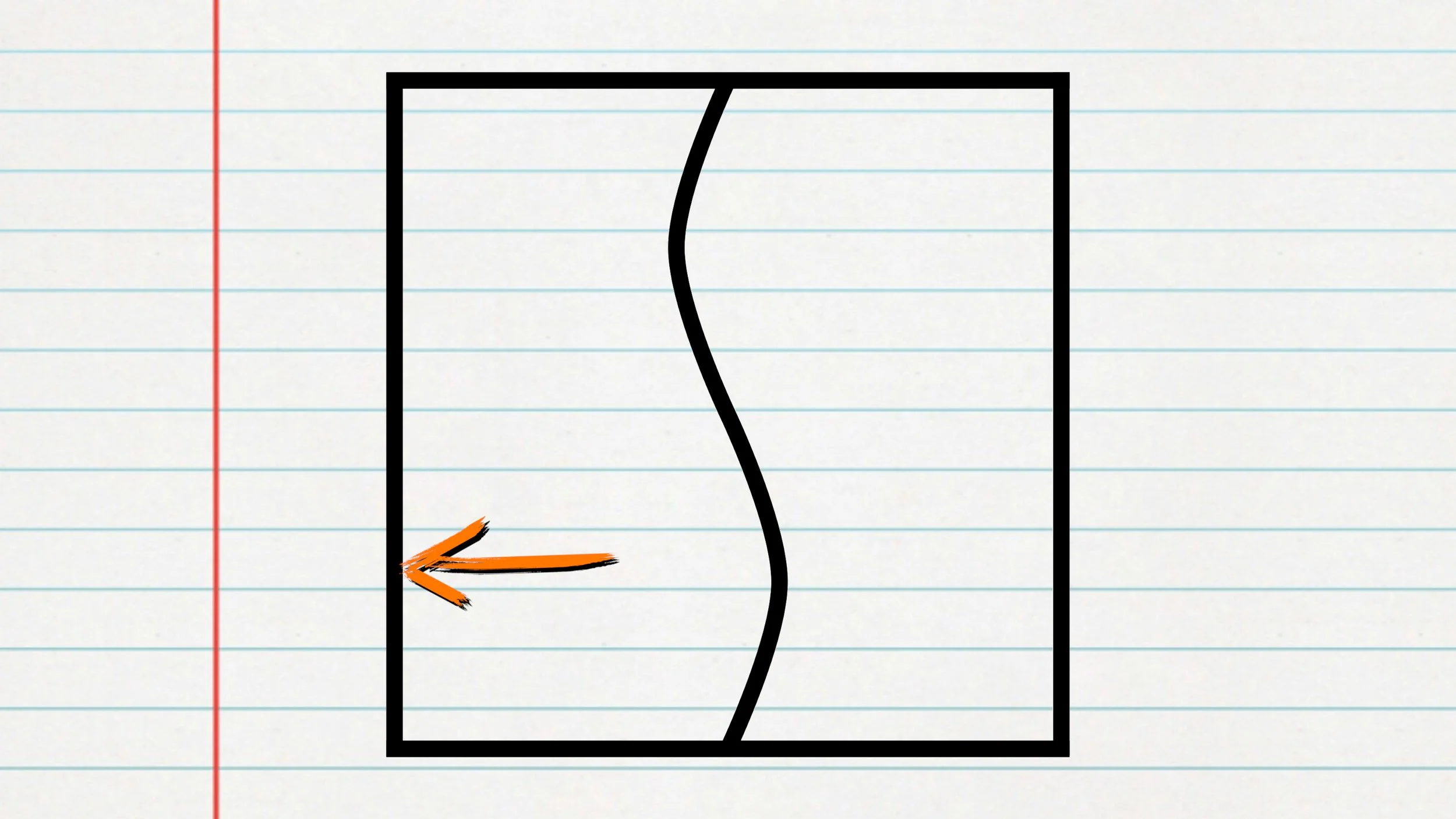

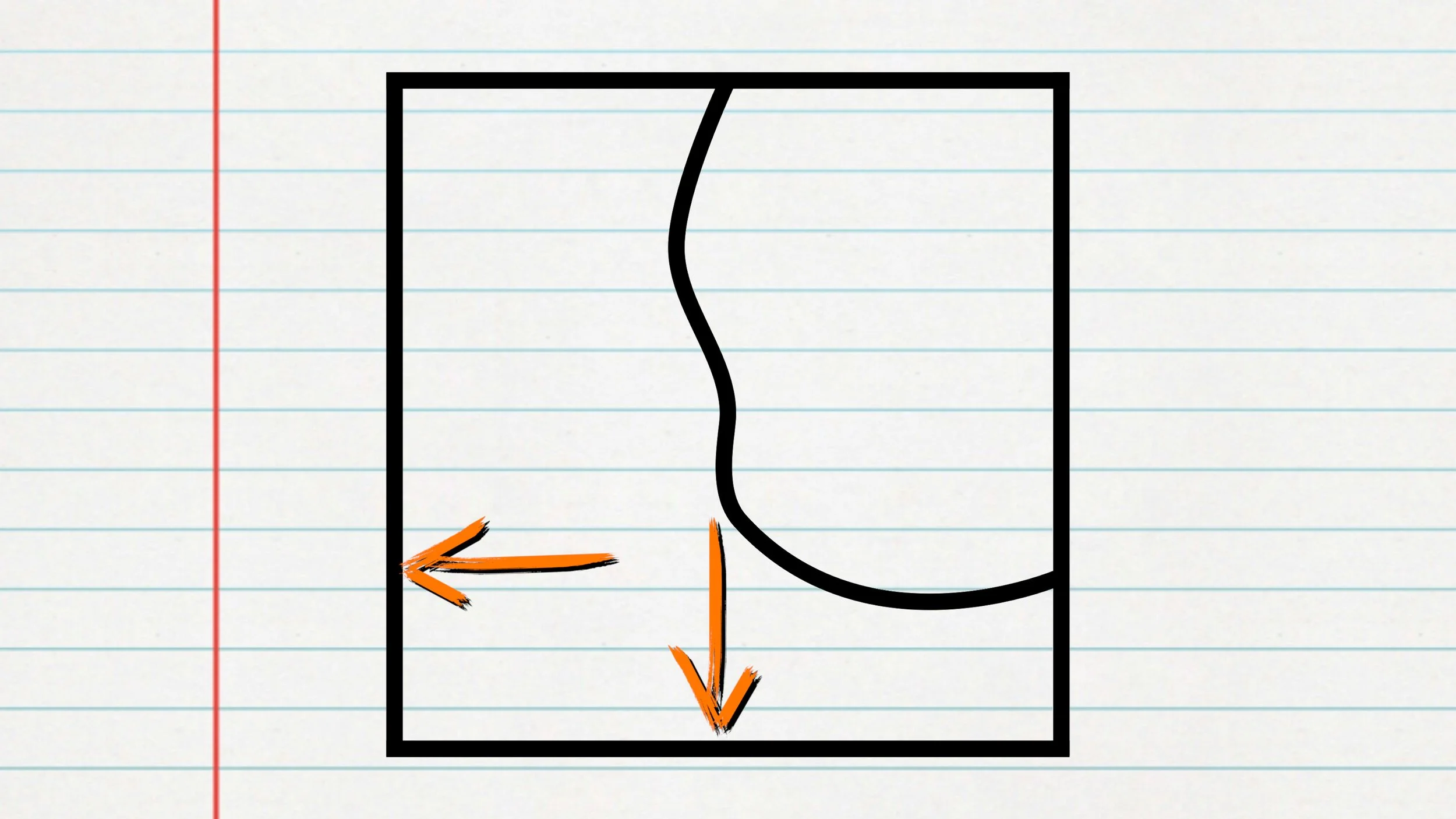

If we want the pieces to stay the same size, we have to scale them up. Move your template lines further out. The distance is equal to the thickness of your saw blade. If your blade is 0.02” thick, you can move one side out by 0.02” or both sides out by 0.01” so they equal 0.02”. You only have to do it on the edge opposite of your cut line. For example, if you cut the board top to bottom, you can make up for the difference by extending the far side. If you have a sharp curve that causes you to cut top to bottom and then left or right, you will likely need to expand the lines on multiple sides.

This may seem confusing or like overthinking. It’s not. You wouldn’t think so if you received the amount of messages that I do from people having issues with pieces not fitting properly and seeking some guidance.

It’s also not a lot of work to solve. I make my own templates so it’s easy for me to simply expand a line outward and call it a day. If you don’t want to modify the template, you can change how you cut. Instead of cutting on the line on that side of the workpiece, cut outside of the line. You can combine techniques. Cut on the line on one side, but outside the line on another side.

How you solve it isn’t as important as knowing that the problem exists and why. If you don’t know it exists, then you will be caught off guard when you do discover it, and may not know why it occurred. Now that you do, you can try different methods and pick the one that works best for you.